Colwick Industrial Estate

Colwick,

Nottingham, NG4 2BB

Projects - Aquifer Storage and Recovery

Aquifer Storage and Recovery (ASR) is a system where at times of surplus, water is deliberately pumped into underground aquifers and stored there for subsequent abstraction. This is usually at times of reduced availability of natural water sources such as during periods of peak demand during the summer months. Although ASR has been developed extensively abroad, development in the UK has been limited. However, in a pioneering move, Thames Water Utilities Limited investigated the feasibility of the technique in north Kent where, historically, peak summer abstraction from the unconfined Chalk aquifer has caused reduced flows in the adjacent River Darent.

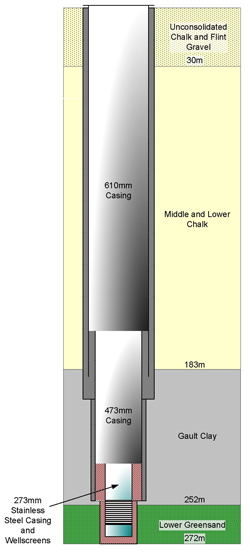

Thames Water developed a trial scheme to store good quality water in the Lower Greensand aquifer which is separated from the Chalk aquifer by 69m of impermeable Gault Clay, thereby isolating the abstraction from the river.

BDF was contracted to drill a trial borehole into the Lower Greensand and carry out subsequent cycle testing. Construction of the borehole involved drilling 198m of 724mm (28.5") hole through the chalk using reverse circulation. This was done with potable water since this hole section was through an existing public water supply aquifer, the Chalk, and close to existing abstraction wells. The Chalk was then cased off at 610mm (24") to isolate it before continuing drilling with mud at 559mm (22") through the Gault Clay to the top of the Lower Greensand at 252m. This section was isolated with an 18" diameter drop-set casing. Finally 20m of Greensand was drilled at 375mm (14.75") to a total depth of 272m. A 273mm (10.75") drop-set stainless steel wellscreen was then inserted through the aquifer section and a gravel pack placed in the annulus.

Construction of the hole was technically challenging with long sections of large diameter hole, heavy casing weights and large cement volumes required. Close control of drilling mud properties was essential to eliminate swelling and balling of the Gault Clay, and to provide temporary support of the unconsolidated Greensands while ensuring an optimum yield of sand-free water.

On completion of the construction phase an extensive period of cyclic pump testing was undertaken. Four cycles of injection, storage and subsequent re-abstraction were carried out, with the total period of each cycle extending incrementally from 6 to 42 days. The static water level in the Greensand was at just 2.5m below ground level and injection pressures exceeded 60m of water at the wellhead so both the test and observation wells were fitted with fully sealed high pressure wellheads. For each cycle mains water was injected into the ASR borehole under step and constant rate test conditions and the effect on the aquifer closely observed and monitored, including collection of water quality samples from a sweetening flow from the base of the observation hole. On completion of the injection phase the in-situ pump was operated to carry out the abstraction phase, again under full test conditions. Since the dynamic water level ranged between 60m agl and 100m bgl particular safety measures had to be implemented to control this wide range of pressures safely.

BDF provided the Client with a very efficient sand-free well and a comprehensive high quality electronic data set from which a detailed and reliable analysis of the ASR potential of the site could be carried out.